Back from the Sand Blasters

The blast company

spet 10-11 hours blasting to complete and turnaround time was about 2 weeks.

The work saved

by having the car blasted is impossible to calculate. Every inch of the car inside

and out is perfectly clean. Even inside the sills and other hidden areas are pretty

clean. The only complaint is that the car now bleeds sand. Spent several hours

blowing air into all the hidden areas and vacuuming, but still get some sand spilling

out. Over time it stopped, but it took 3-4 months of banging on the shell and

turning the car around on the rotisserie to get all the sand out.

The work saved

by having the car blasted is impossible to calculate. Every inch of the car inside

and out is perfectly clean. Even inside the sills and other hidden areas are pretty

clean. The only complaint is that the car now bleeds sand. Spent several hours

blowing air into all the hidden areas and vacuuming, but still get some sand spilling

out. Over time it stopped, but it took 3-4 months of banging on the shell and

turning the car around on the rotisserie to get all the sand out.

The down side

of getting the metal perfectly clean is that now every hole and dent is clearly

visible. When I inspected the car at the blasters, the owner said the car looked

like it had been in a machine gun battle. hundreds of holes had been punched into

the body by the bondo bodgers and even more body damange I didn't expect.

The down side

of getting the metal perfectly clean is that now every hole and dent is clearly

visible. When I inspected the car at the blasters, the owner said the car looked

like it had been in a machine gun battle. hundreds of holes had been punched into

the body by the bondo bodgers and even more body damange I didn't expect.

In addition to

getting the car blasted, the shop had a large powdercoating oven which they used

to bake the body. The car was cooked at 400 degrees for 3 hours. This cures the

metal, and melts most of the old seam sealer out and any remaining lead. According

to the shop the steel will resist flash rust much longer after cooking. The hood

sections had been repaired in a number of places and were far from perfect, fortunately

no major problems in the sheet metal which will force replacement.

In addition to

getting the car blasted, the shop had a large powdercoating oven which they used

to bake the body. The car was cooked at 400 degrees for 3 hours. This cures the

metal, and melts most of the old seam sealer out and any remaining lead. According

to the shop the steel will resist flash rust much longer after cooking. The hood

sections had been repaired in a number of places and were far from perfect, fortunately

no major problems in the sheet metal which will force replacement.

The rear end damage

is pretty extensive, Blasting didn't help, holes that were 1/4" turned into

1/2". Metal that was a little thin was lost all together. Still its good

to know where the problems are. Lots of work ahead getting this body back into

good condition.

The rear end damage

is pretty extensive, Blasting didn't help, holes that were 1/4" turned into

1/2". Metal that was a little thin was lost all together. Still its good

to know where the problems are. Lots of work ahead getting this body back into

good condition.

The underside of

the car was pretty solid except for the trunk tub, I found some small rust areas

in the wheel wells, but these were easy to cut out and patch.

The underside of

the car was pretty solid except for the trunk tub, I found some small rust areas

in the wheel wells, but these were easy to cut out and patch.

The trunk tub as

mentioned before is messy. Not practical to save this. I'm sure if I had unlimited

time I could do it, but it will be better to cut it out and buy a new one.

The trunk tub as

mentioned before is messy. Not practical to save this. I'm sure if I had unlimited

time I could do it, but it will be better to cut it out and buy a new one.

Here you can see

some of the front fender damage, along with the rear hatch. The hatch is probably

just about the only part which doesn't need any metal work before painting.

Here you can see

some of the front fender damage, along with the rear hatch. The hatch is probably

just about the only part which doesn't need any metal work before painting.

Back in the garage,

the blasting took about 2 weeks. The shop I used charged about $80 an hour to

do the job. The total was $900 to get everything blasted. This included the Sub

frame, All the bonnet parts, the rear suspension frame, the shell, doors, a few

small parts etc. If anyone in the bay area is looking for a good blaster contact

me via email.

Back in the garage,

the blasting took about 2 weeks. The shop I used charged about $80 an hour to

do the job. The total was $900 to get everything blasted. This included the Sub

frame, All the bonnet parts, the rear suspension frame, the shell, doors, a few

small parts etc. If anyone in the bay area is looking for a good blaster contact

me via email.

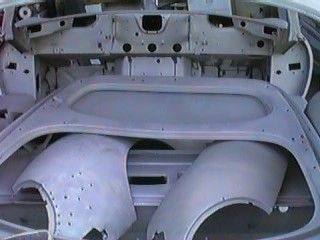

Another shot of

the rear end mess. Not much to say except what a mess. At least the damage appears

to be localized to this part of the car. The hatch fits well, and if I can get

the back fixed it should all be OK.

Another shot of

the rear end mess. Not much to say except what a mess. At least the damage appears

to be localized to this part of the car. The hatch fits well, and if I can get

the back fixed it should all be OK.

I discovered a

few problems after blasting. First the cowl on the passenger side had rust out

at the bottom where it meets the sill. I'll cut about 2 inches of it out and replace.

Also the inner sill was warped. I fortunately have access to bang out most of

this from below, but will also need to pull from the top, and fill in some of

the damage with lead.

I discovered a

few problems after blasting. First the cowl on the passenger side had rust out

at the bottom where it meets the sill. I'll cut about 2 inches of it out and replace.

Also the inner sill was warped. I fortunately have access to bang out most of

this from below, but will also need to pull from the top, and fill in some of

the damage with lead.

A car load of clean

parts. Door shells, front bottom of the bonnet, sub frames etc. All ready for

prep and prime. I removed the door skins before sending the shells out for blasting.

I discovered a number of problems which I hadn't expected hidden under bondo,

more later on these problems.

A car load of clean

parts. Door shells, front bottom of the bonnet, sub frames etc. All ready for

prep and prime. I removed the door skins before sending the shells out for blasting.

I discovered a number of problems which I hadn't expected hidden under bondo,

more later on these problems.

The lower bonnet

tub had a hard life. A small amount of rust and a medium amount of damage. Fortunately

nothing can't be fixed. The other parts of the hood were also a little rough,

but all will be able to be salvaged.

The lower bonnet

tub had a hard life. A small amount of rust and a medium amount of damage. Fortunately

nothing can't be fixed. The other parts of the hood were also a little rough,

but all will be able to be salvaged.

Here its easy

to see the condition of the floors and the inner sill. Also some damage to the

main cross support. The floor will be easy to weld up and flatten out the dents.

Hammer and dolly, mig welding, and a stud welder will be a must to correct this.

Body Work Begins!

Here its easy

to see the condition of the floors and the inner sill. Also some damage to the

main cross support. The floor will be easy to weld up and flatten out the dents.

Hammer and dolly, mig welding, and a stud welder will be a must to correct this.

Body Work Begins!